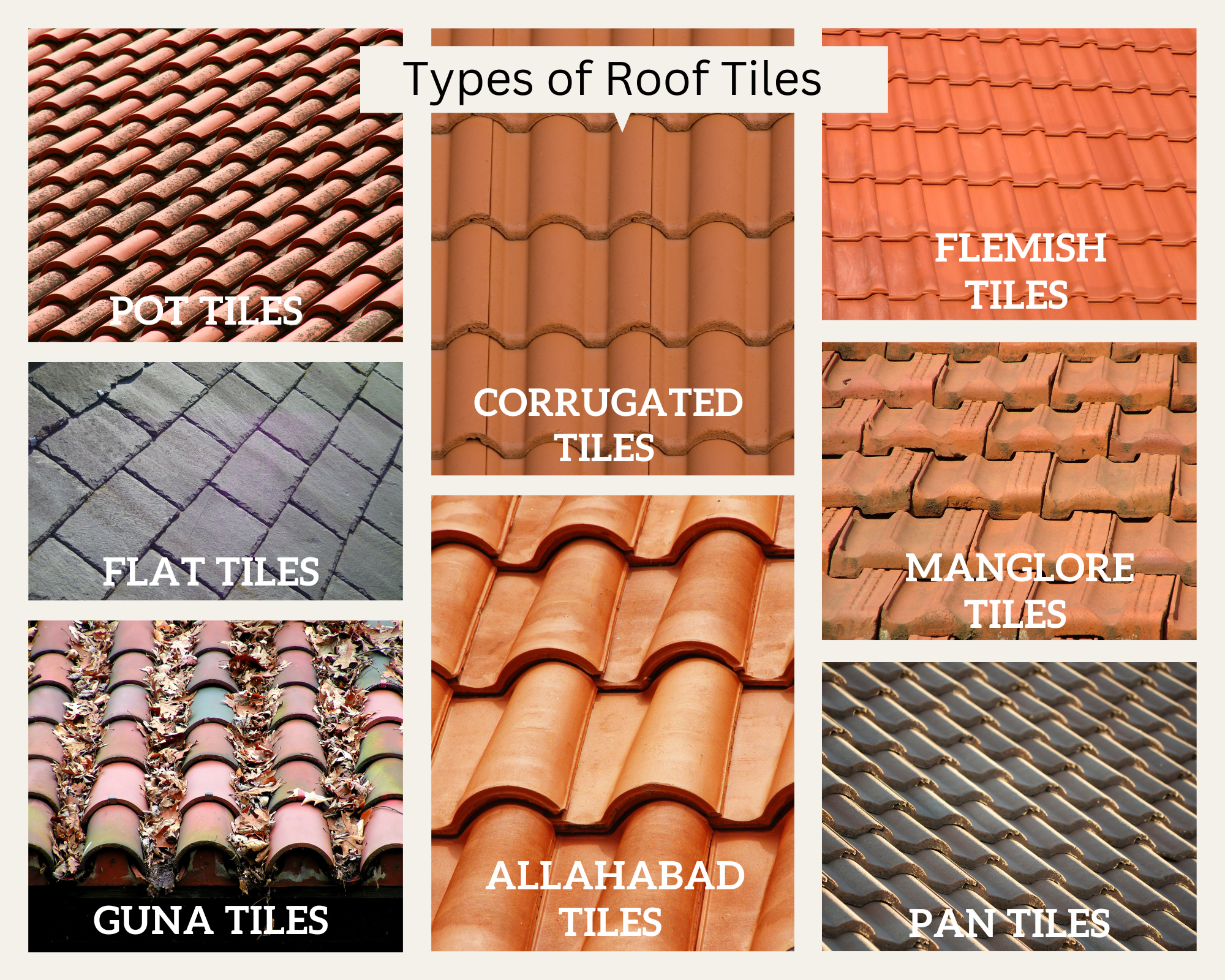

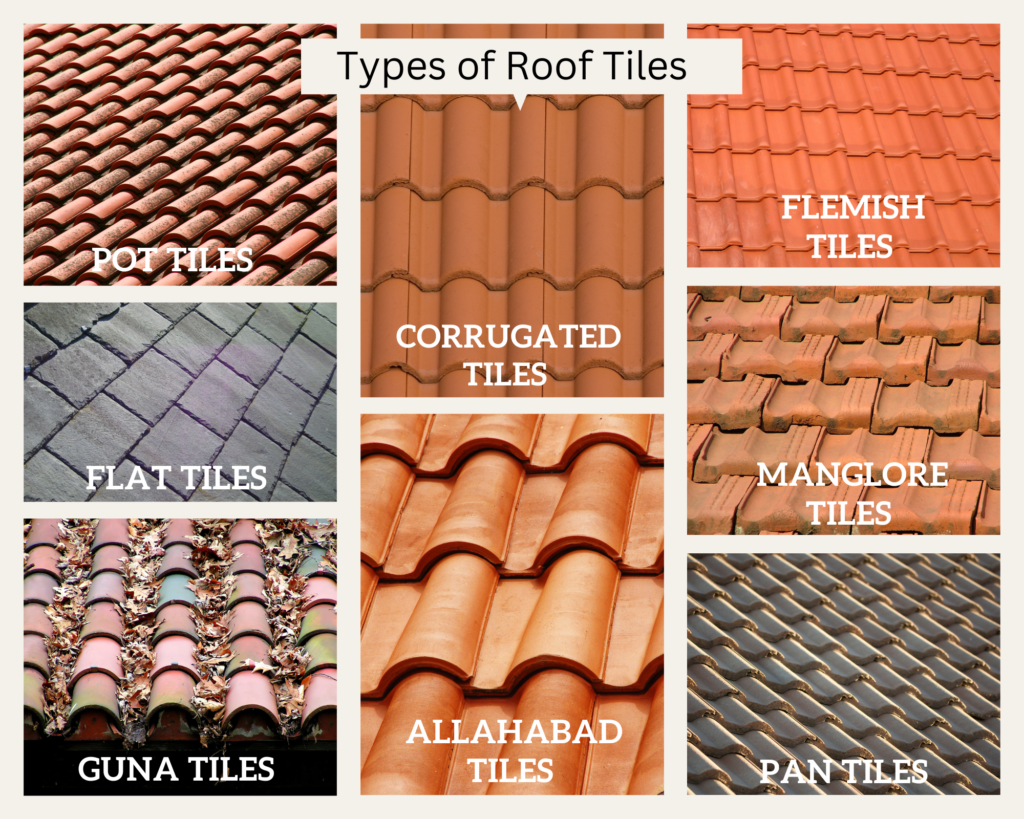

Types of Roof Tiles in India | Roof Tiles Types

Roof tiles may be defined as thin slabs of brick which are burnt in kilns. They are thinner than bricks. These tiles are used to serve as covering for pitched roof. Various types of roof tiles are available in the market in different shapes and patterns. Their important varieties are as follow:

- Allahabad roof tiles

- Corrugated roof tiles

- Flat roof tiles

- Flemish roof tiles

- Guna roof tiles

- Manglore roof tiles

- Pan roof tiles

- Pot roof tiles

Allahabad Tiles

These tiles are made from selected clay. The mouding of clay is done under pressure in machines. The burning of these tiles is done in such a way that they attain more strength. These tiles are provided with projections so that they interlock with each other, when they placed in position. The tiles of special shapes are made for hip, ridge and valley portions of the roof. These tiles are extensively used in north-western india.

Corrugated Tiles

These tiles have corrugations and when they are placed in position, a side lap of one or two corrugation is formed. The placing of such tiles on a roof gives an appearance of corrugated galvanized iron sheets. These are handsome in appearance, but they can easily be blown away by a violent wind.

Flat Tiles

These are ordinary floor tiles. To fix them on battens, two or more holes are provided on their surface. The suitable laps are provided at side and edges.

Flemish Tiles

These tiles have got the shape of letter ‘S’ with dimensions as 350 mm x 225 mm x 12 mm and they are prepared with the help of a mould. These tiles do not form a good covering as the plain tiles and they are used only for sheds.

Guna Tiles

These are hollow tapered burnt clay tiles. They are conical in shape with a base of 100 mm diameter at the broader end and 75 mm at the narrower end. The thickness of the annular ring is 6 mm. These tiles can be manufactured on the potter’s wheel and on account of their conical shape, they can be inserted one into another so as to form a ring of guna tiles. The ring may be made of suitable shape such as circular, elliptical, parabolic, etc.

Also Read- Design Strategies for Hot and Dry Climate

Manglore Tiles

These tiles are of flat pattern and they are provided with suitable projections so that they interlock with each other, when placed in position. These tiles are red in color and made double channeled basel Mission Manglore pattern. The special Manglore tiles are available for hip, ridge and valley portions of the roof. It is found that about fifteen Manglore tiles are required for covering one square meter of roof area.

These tiles are manufactured on large scale in South India especially at Manglore, Cochin and Calicut. This industry was established in the early 19th Century by German Missionaries. The first unit manufacturing manglore pattern tiles was started at Morvi, Saurashtra in 1951 and at present, more than 200 units are working in this area. Thus, Morvi has become the Bangalore of Gujrat State and some other units, about 30 or more, are also located in Balsar and Surat districts of the Gujrat State.

The Manglore pattern roofing tiles are becoming popular in rural and semi-urban areas and they are used by middle and low income group people because of various reasons such as architectural effect, scarcity and rising prices of other substitutes, growth of population, etc. The life of these roofing tiles is estimated as about 25 years with replacement of about 5% per year.

Dimensions of Manglore Tiles

| Effective length | Effective width |

| 320 mm | 210 mm |

| 340 mm | 215 mm |

| 350 mm | 220 mm |

Pan Tiles

These tiles are short and heavy. They are less curved in section than pot tiles. Such tiles are moulded flat first and then they are given the required curvature by moulding in suitable forms. Drying and burning of tiles are done carefully to get better quality of tiles. These tiles are of length 330 mm to 380 mm and of width 230 mm to 280 mm.

Pot Tiles

These are ordinary half round country tiles and they are also known as the locking tiles. They are prepared on potter’s wheel and shape is given to such tiles by a potter with his wet hands. The polishing of inner and outer surfaces is done either with a wet cloth or a wetter strip of leather.

These tiles are semi-circular in section and taper along the length of 300 mm with diameter of about 230 mm at larger end and of about 200 mm at smaller end. They are placed on the roof with their concave and convex sides uppermost alternatively so that they can become self-locked. An overlap of at least 80 mm is provided at edges, when these tiles are used.

These tiles are liable to break easily and hence they require frequent replacement and repair which may prove to be extremely difficult.

Following are the advantages of pot tiles:

- These tiles are less liable to be displaced by the birds.

- These tiles may be used as a sole covering to the roof.

- The pitched roof may be made completely leaf proof because of the fact that good drainage is ensured by these tiles even when the slope of roof is less.

ALSO READ –